Engineering Plastics Molding

Meridian molds a variety of products for customers in diverse markets where there is a need for specific properties for challenging applications.

For High Heat, High Performance Applications

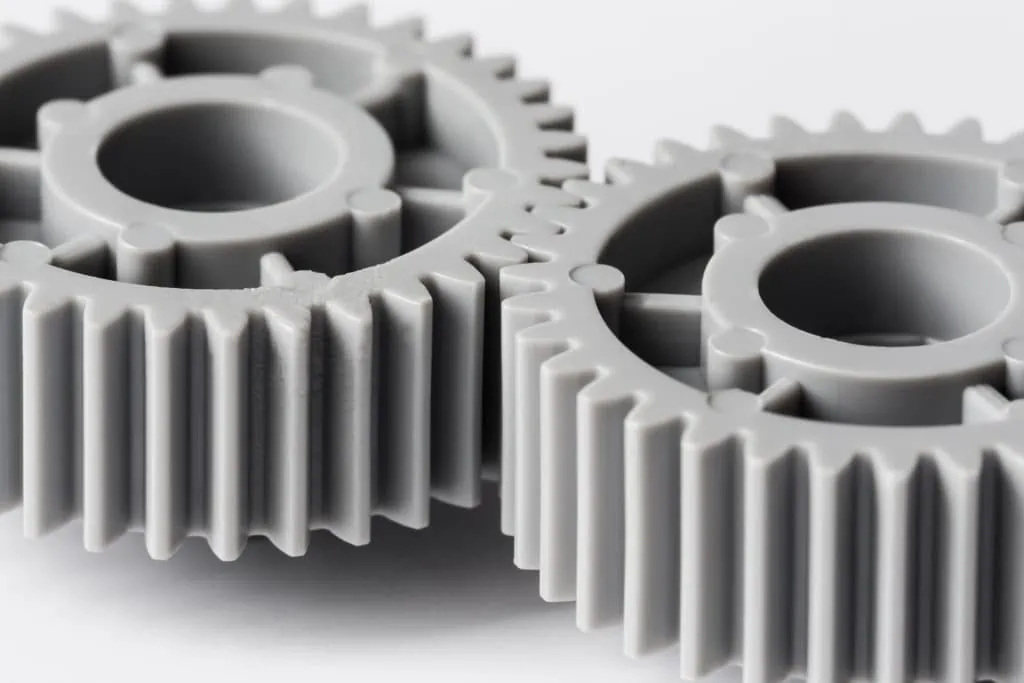

Many applications require engineering grade thermoplastic polymers that are chemically resistant in harsh environments. There are certain processing disciplines necessary to achieve the optimum performance from the resin, which Meridian achieves through extensive training and history. These include semi-crystalline high performance resins such as PEEK and polyphenylene sulfide (PPS).

In water and steam environments, high performance amorphous resins are more suitable, such as polyphenylsulfone (PPSU) and polysulfone.

Engineering resin choices are specified to minimize the erosion of structure and properties in these harsh environments with resin manufacturers’ data and feedback. Meridian helps with specific data to determine if a customer’s choice is the best suited engineering grade once all factors are considered from the Material Recommendation form.

Moderate Heat and Performance Applications

Semi-crystalline moderate performance resins such as nylon and acetal are good choices in many applications where chemical resistance is required. For example, these are commonly used in automotive applications such as under the hood and fuel delivery components.

Amorphous resins can be more suitable for dimensional stability with low warpage and excellent IZOD impact strength, including polycarbonate (unfilled and glass-filled). The clarity achievable in clear polycarbonate is an excellent choice for lenses and light pipes with the added benefit of a wide range of translucent variation.

Industries and Applications

Particularly suitable industries include: Petroleum, Aerospace, and Irrigation systems.

For example:

- High temperature lamp housings

- Fracking valves

- High pressure irrigation valves

- Drive train components

- High performance gears